This is my first time of making a modification to a keyboard. In fact, I done

it to my first mechanical keyboard ever! The reason I want to do this is

because I'm not happy with the sound this keyboard made when typing. The sound

can sometimes be heard from outside the room so I want to make it quieter. Of

course, I was afraid of making my keyboard worse because lubing isn't

something that can be understood so easily by a newbie. But I thought, if I'm

not going to try it now, then I'll never be able to find out whether I could

actually do it or not

(lol wish I could apply this trait of me in life all the time T.T) . I saw some videos of people lubing their keyboard and I'm so amazed

by the clear sound difference of before and after lubing. Thanks to YouTubers

and Reddit users who made all those tutorials, I'm able to collect a few

knowledges and convinced to proceed with this little project.

At first, I thought about documenting everything in a video because it's my

first time but I was too focus to finish the lubing. I do have a few pictures

and videos so.. yay...

What I have here are: Krytox 105 lubricating oil and Permatex dielectric

tune-up grease. I bought the repacked ones, so it's much cheaper and worth it

for one-time use. Because my keyboard switch is brown switch (not

Cherry MX), I read it online that Krytox 105 is the best for beginners. As for

the dielectric grease, I chose that because it's the only thing that the shop

I bought from got. Then I have 2 brushes, a 5 ml luer-slip syringe and a 18

gauge needle. It was supposedly 18 gauge BLUNT NEEDLE but I cannot find it so

I ended up buying the one that is used for medical. Another thing that I use

but not in the photo are sound dampener foam and o-ring dampener.

The very first thing I do is putting 2 o-rings under the keycaps. I tried

putting only 1 and 3 but using 2 produce the best result for me. With 1, you

can barely hear any difference. With 3, although it's quieter than 2, the

typing feeling is super bad. Not recommended.

And then, here we comes to the hardest part. Getting the top cover open! I

don't record anything because it was such a mess! After a few minutes of

trying to get it open, I started to lose my patience and use tremendous force

to pry it open. As the result of my impatience, I broke 2 of these things that

hold the top and bottom cover together. Thankfully, the damage isn't that

serious because there are 4 of those things still intact.

After managed to get the cover open, I disconnect the wire that connects to

the board and start to prepare myself for lubing. At the time I'm doing it,

this is the scariest part for me. Any mistake could make my switch damage. I

tried to be careful not to overlube the switch and pray to the God nothing is

damage. The first thing I lube is the stabilizers. By using a thin paint

brush, I put some dielectric grease on it. No photo because again, it's quite

a mess. This is because I was suppose to use INTERDENTAL BRUSH for this but

because the shop I bought all my things from doesn't have it, I use a paint

brush. Although it's thin, I stil think it's not thin enough so it's a bit

hard to get the grease in there.

When the stabilizers are done, I started to lube the switches with Krytox 105.

For this, I had to be super careful. I thought it would be easy to drop those

oils from a syringe but it turns out, it's quite hard to control the amount of

oil coming through the needle. Probably it's because I'm using the medical

syringe and needle. Maybe. After lubing a few switches, I made a sound test to

see if there's any difference or not. When I feel the difference, I proceed

until the last switch.

When everything is done, it's the moment of truth. I reconnect the wire to the

board, turn it on and start testing it with Switch Hitter. THANK GOD ALL THE

KEYS WORK PERFECTLY!

Before putting everything back together, I fill the case with some sound

dampening foam. I use a foam for automotive and studio use, the one that’s

egg-shaped, that’s why it looks ugly like that. Really not recommend to use

it. In fact, use an EVA foam with thickness between 3-6mm. The one I use is 1

cm so I have to trim it.

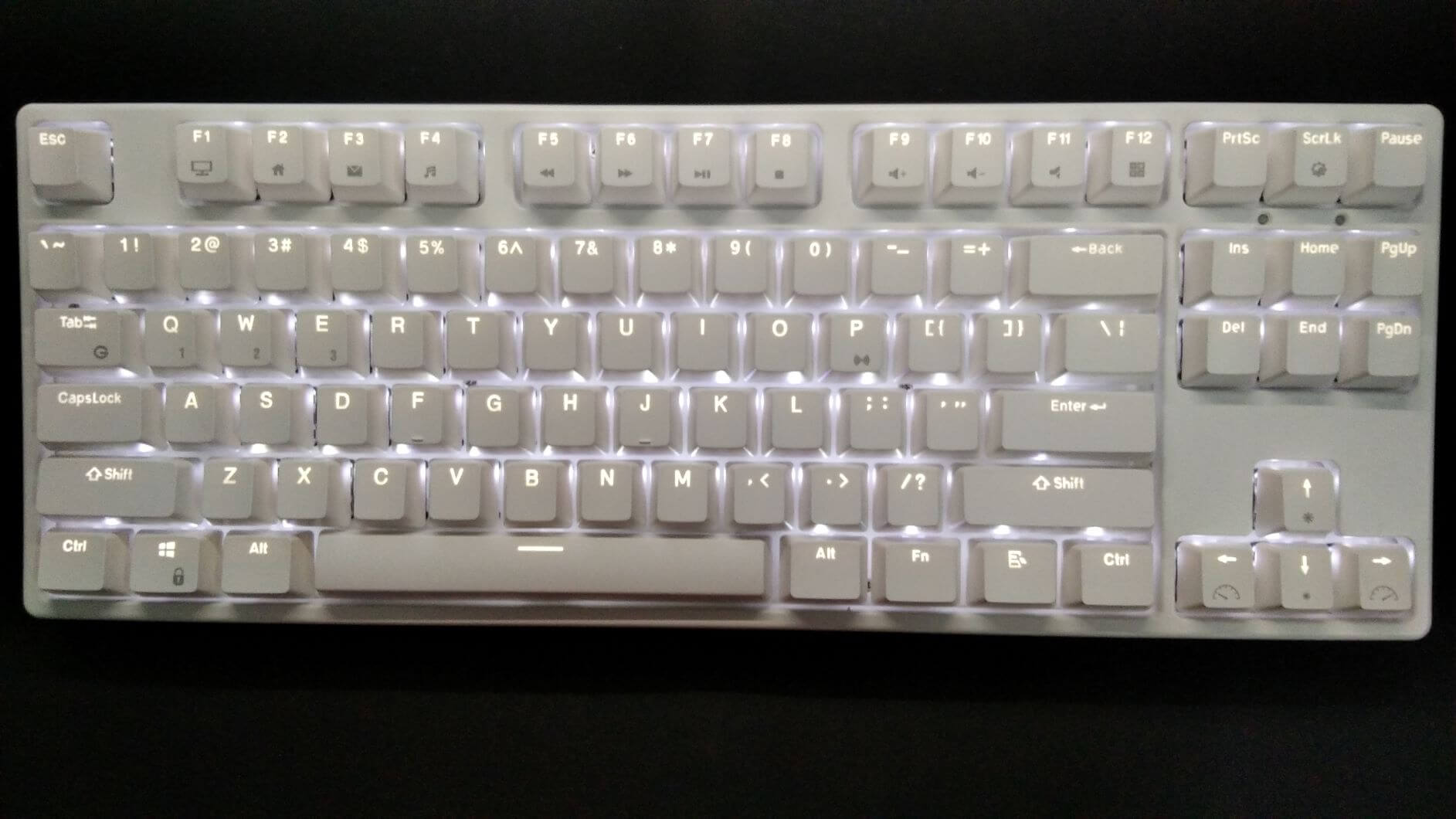

And the result?

Very satisfying! cries

Sorry for the bad quality video because I only have a potato phone. The

microphone (earpod microphone) is placed at the same place which is beside the

keyboard. The switch feel soooo smooth and it’s quieter. But if you look

carefully, the LED lights up longer after each pressed after it’s lubbed. It’s

not really a big deal, just that I prefer when it lights up shorter.

So, that’s it! I did it! Really worth the risk I must say. But because having

a smoother and quieter keyboard is more of a personal preference and will void

your keyboard warranty, I 8⁄10 would recommend everyone to lube their

keyboard. If anyone wants to try it out to their brown switch keyboard, you

can purchase some of the things I use from the shop I linked below. For a 87

keys keyboard, 2 ml dielectric grease and 4 ml oil should be more than enough

for one-time use!

Links:

Disassemble, foaming and lubing reference:

YouTube

Lubing with syringe method reference:

Reddit

Shop:

keys.my

No comments:

Post a Comment